How We Enhanced an AI System for Auto Defect Detection

A UK-based technology company developing automated vehicle inspection systems for major car manufacturers. The company turned to us for machine learning expertise to refine and scale their AI solution for automated vehicle inspection. Our specialists optimized model training processes, improving accuracy and speed while reducing operational complexity.

Key results

| 95% | coverage of every vehicle during inspection. |

| 50% | inspection error reduction. |

Project scope

To help the client enhance their vehicle inspection systems, we took a phased approach:

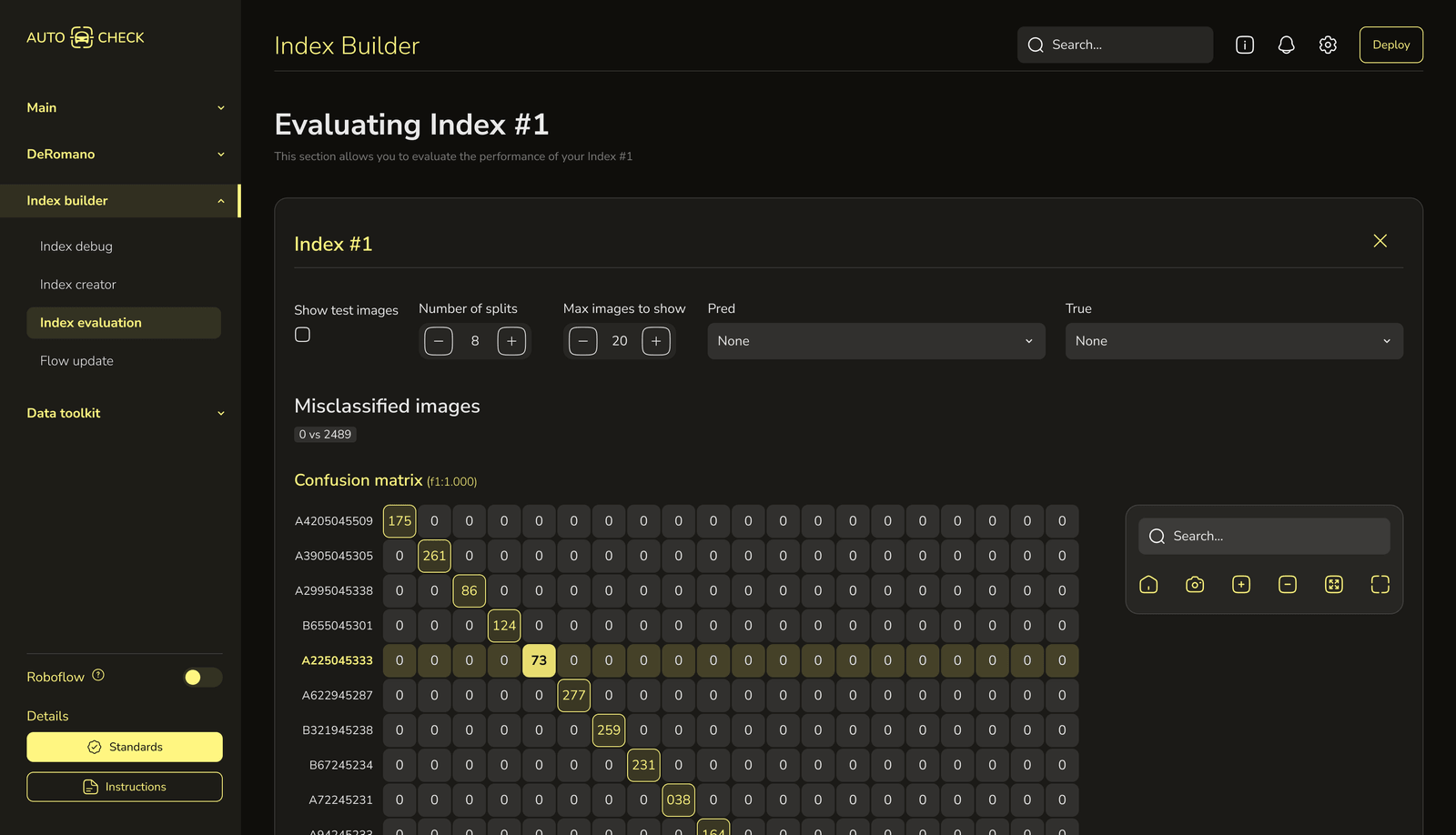

Rethinking model architecture

The work began with analyzing the existing model training process. The previous approach relied on numerous models, each responsible for identifying a specific car element. This setup created unnecessary complexity and slowed down the development of new specifications.

We restructured the training pipeline, introducing a unified model that could handle multiple elements within one framework. This shift reduced training time and simplified maintenance.

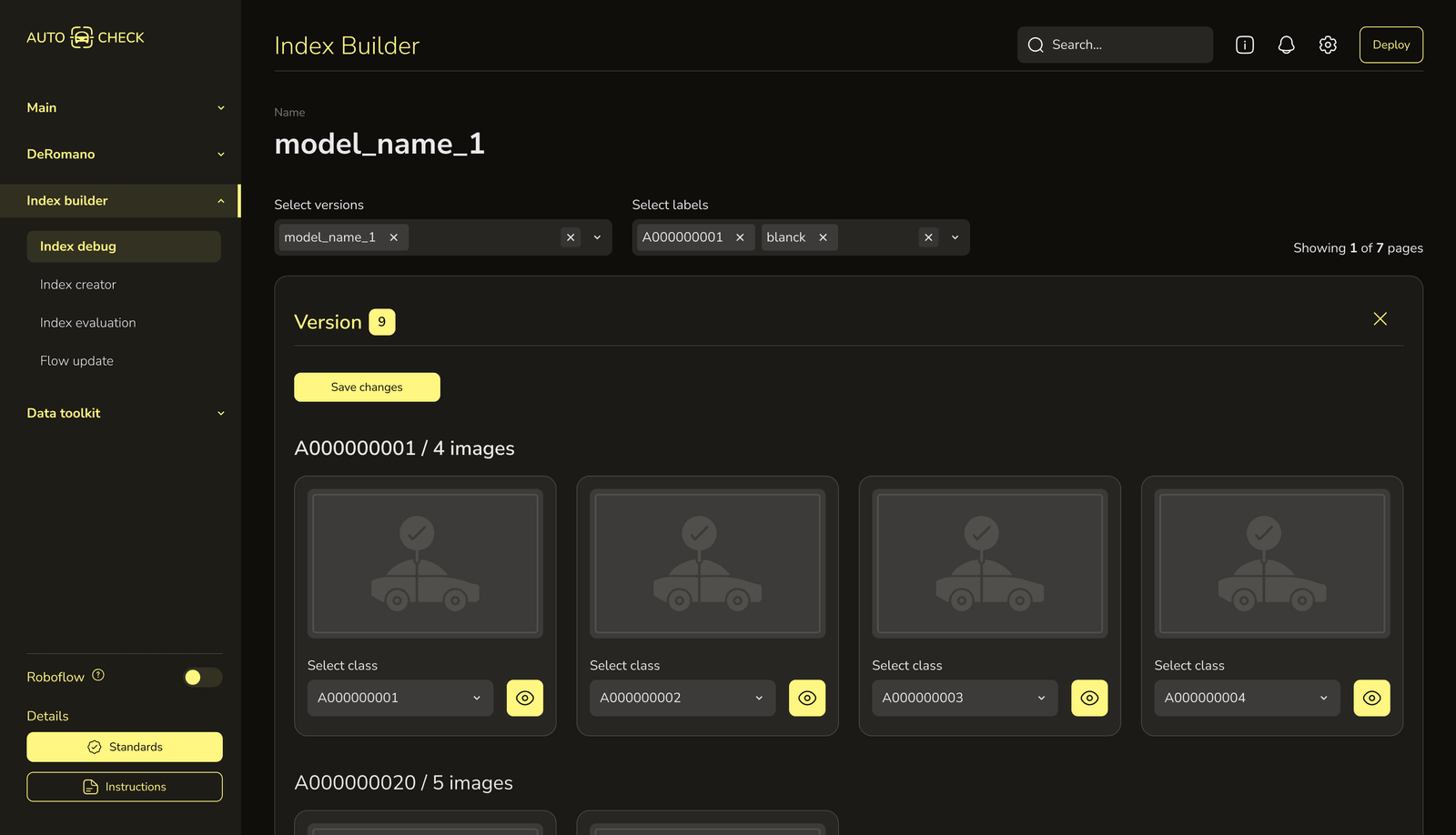

Optimizing data management and version control

Next, we focused on improving how data was processed and managed. Old datasets and inconsistent versioning made it difficult to track changes and reuse training results. The new workflow addressed these issues by introducing clearer version control and reducing redundant processing steps.

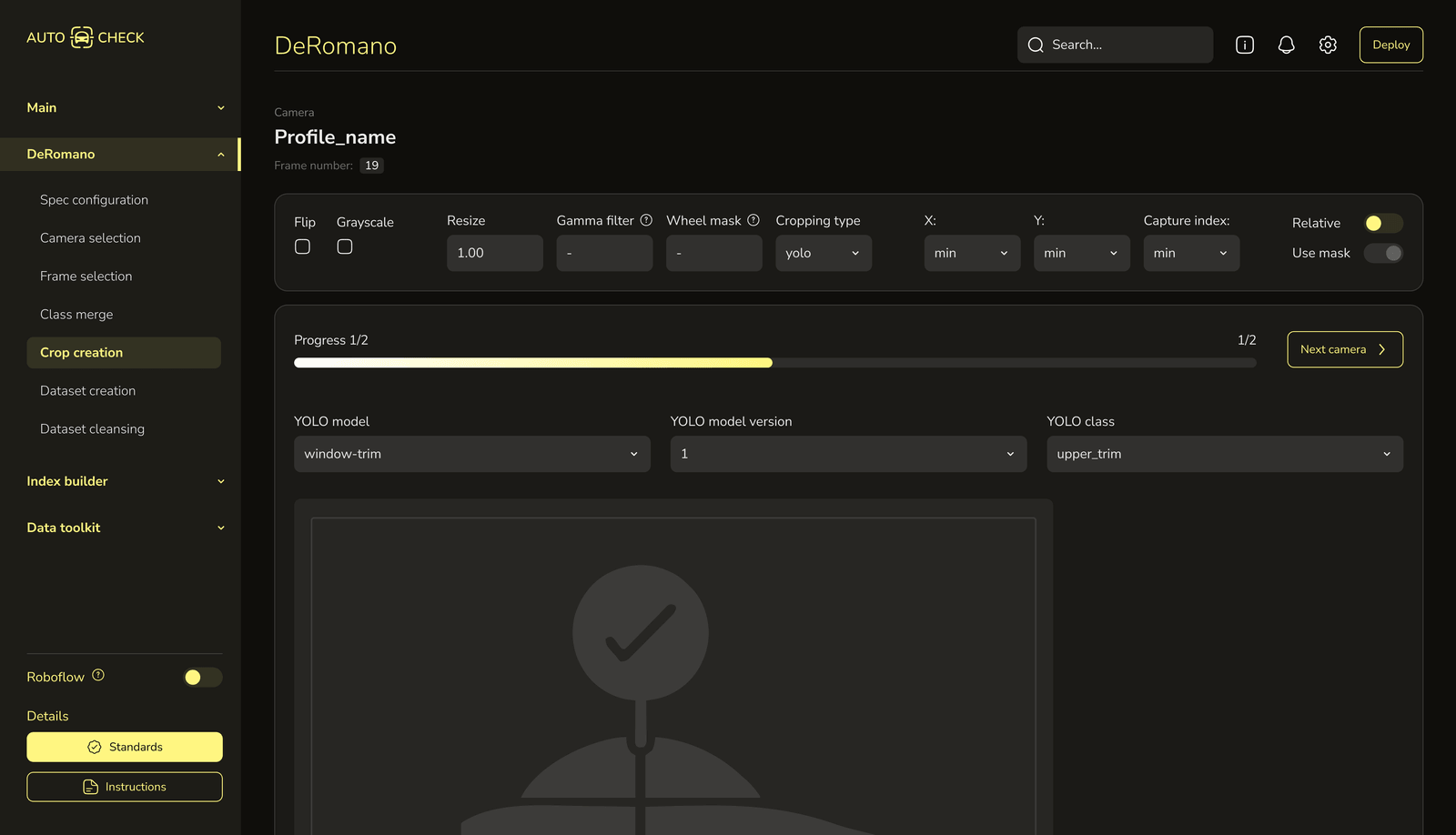

Implementing RoboFlow for model training

Another key improvement was the integration of RoboFlow, a platform that streamlined dataset management and model training. We adapted the client’s systems to use RoboFlow for annotation, training, and signaling models. This allowed faster delivery of new specifications and simplified collaboration within the team.

Additional improvements

Alongside optimization, our expert helped transform several proof-of-concept models into production-ready solutions. The updated architecture introduced new microservices for managing specifications and delivering model results. This ensured smoother interaction between inspection modules and enabled faster onboarding of new vehicle types.

How the improved system works

After our team optimized the ML workflow and restructured the training pipeline, the vehicle inspection system became faster, more stable, and easier to scale. The updated process combines automated image capture, efficient data preparation, and improved model management to deliver reliable real-time inspection results.

Unified inspection pipeline

Instead of relying on multiple small models, the system now uses a unified framework capable of processing different car components within a single workflow. This structure reduces maintenance time and simplifies the introduction of new specifications.

Streamlined data preparation

The new data management logic automatically filters, normalizes, and stores captured images, ensuring version consistency and better traceability. This reduces manual routines and prevents training delays caused by outdated datasets.

Faster model training and deployment

Thanks to RoboFlow and the unified MLFlow tracking setup, new models can be trained, validated, and deployed much faster. The entire process, from dataset annotation to production release, is now fully traceable and easier to reproduce.

Real-time defect detection and reporting

The optimized models detect mismatches, missing parts, or incorrect configurations in near real-time. Results are displayed through an interface built with Streamlit, helping production teams quickly verify issues and make decisions on the spot.

Continuous improvement cycle

Using RoboFlow and the unified training pipeline, new data can be added quickly. Each update helps retrain and refine the models, improving classification accuracy and allowing the system to adapt to new car models and OEM requirements.

Tools & technologies

Do you want a solution like that?

Or do you have another idea and need a tech partner to implement it? Aristek is here to help.