These days manufacturers are able to collect more data than ever before. This data helps them gain an insight into their processes, providing the chance to lower their costs and time-to-market while increasing revenue.

The manufacturing industry comprises of many different processes so it is hard to generalize, but we can highlight the most common areas in which big data has made a key impact:

1. Quality control

Improvements in quality control help prevent product recall and the losses associated with these. Big data can also be used to speed up time-to-market. Intel, for example, used AI to gain valuable insights in order to reduce product validation times, cutting out hours of work by engineers and the costs associated with this. AI also helped to identify which tests were redundant allowing Intel to remove them, eliminating 70% of the tests.

2. Increased revenue through process optimization

Big data is being used by manufacturers to find out which processes and input are the most impactful to output. In addition more and more manufacturers are using IoT (Internet-of Things) sensors to collect data leading to huge savings in process costs.

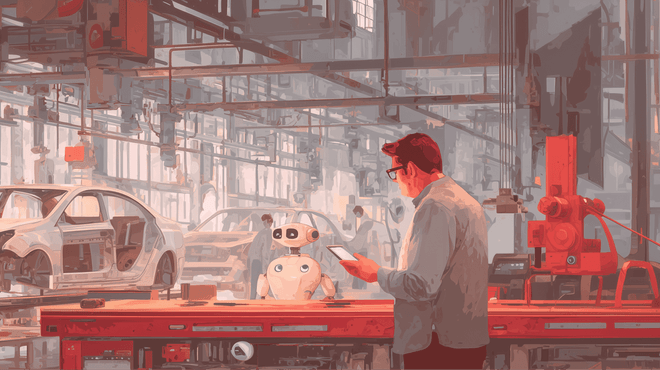

3. Forecasting preventative maintenance needs

IoT, allows manufacturers to use data from machines to plan preventative maintenance and avoid unnecessary downtime. The data shows past performance and this is assessed using Predictive Analytics to predict future maintenance needs. Data highlights when and why a part failed in the past allowing pre-emptive replacement. Downtime can be avoided or scheduled to minimize disruption and loss of output and make sure machinery is maintained to prevent breakages.

4. Inventory management

Effective inventory management keeps costs down and helps maintain output and time-to-market. Keeping raw materials at optimum levels, avoiding waste and looking at when demand for production is highest all keeps manufacturing costs down while maintaining revenue. Supply chain risk identification also helps to keep things flowing well.

Far from being limited to inventory alone, the data can also look at market forces, production times and output and logistics.

Manufacturing still faces a challenge with big data

Only 33% of the data currently being collected is useful and manufacturers are only using about 2% of this. To address this they need to look at some of the challenges such as data security, scalability and maintenance.

Although cloud computing is useful to handle the data they still need to make sense of it, so AI, machine learning and simulation modelling is of help. Simulation software like Simio can be of help in-house and outsourcing to specialists is always an option. Whatever route they choose, manufacturers need to leverage the available resources if they are to harvest the full fruit of their valuable data.