Time is money – this is one thing that is true in any industry. In manufacturing this rule is even sharper because every delay, defect, or unplanned stop has a direct cost. Most companies already track these issues, yet the volume of data behind them grows faster than teams can process.

In this article, we look at how AI assists manufacturers, what measurable benefits it brings, how it is working in real plants and what businesses can expect when applying AI tools in their own production cycle.

How widely is AI used in factory automation today

First, let’s take a broad look at the AI market in manufacturing.

The global market for AI in manufacturing is projected to grow from 7.6 billion dollars in 2025 to about 62.3 billion dollars by 2032. This corresponds to a 35.1% compound annual growth rate across the period.

Asia Pacific holds the largest share, close to 41.8% in 2024, which reflects the scale of its production networks and the speed of technology adoption.

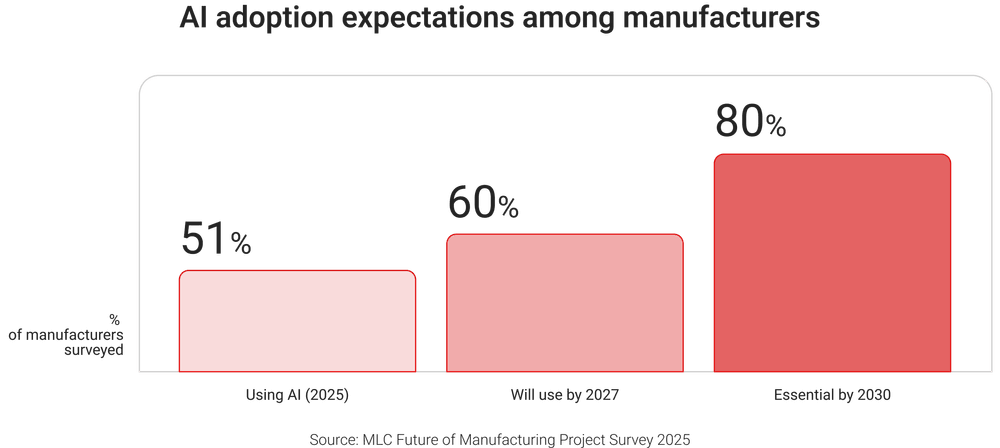

Europe follows the same direction. A survey by the National Association of Manufacturers shows that by 2025, 51% of respondents report using AI in one form or another.

60% of manufacturers surveyed plan to implement AI by 2027, and for 80% of respondents AI integration is an essential part of their growth strategy by 2030.

The numbers show expansion, but they also raise a practical question: what do companies mean when they say they “use AI”? In manufacturing, this can refer to several unrelated tasks. One plant may automate visual inspection. Another may focus on predictive maintenance. Others may use AI for demand forecasting, planning, or technical support.

In the next chapter, we’ll zoom in and examine the specific technologies companies implement when adopting AI.

Which technologies exactly manufacturers are adopting

To understand what companies actually adopt, we need to outline the technologies grouped under the term AI.

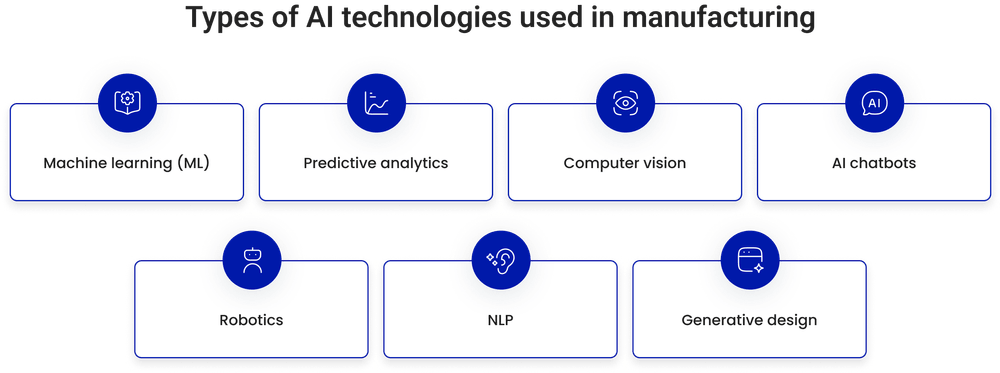

In manufacturing, AI is a set of methods that process operational data and support decisions across design, planning, production, logistics, and maintenance. These can include:

- Machine learning, used to detect regularities in production data and classify outcomes during quality checks or process monitoring.

- Predictive analytics, which forecasts equipment conditions or supply requirements based on historical patterns.

- Computer vision, applied to image or video streams for defect detection, assembly verification, or safety monitoring.

- Natural language processing, which helps operators retrieve instructions, search documentation, or interact with technical systems through text or voice.

- AI chatbots, used to answer practical questions from technicians, production teams, or customers about parts, procedures, or status updates.

- Robotics equipped with adaptive decision logic that adjusts movements or actions based on sensor readings.

- Generative design tools, which propose alternative part geometries or configurations based on input constraints such as weight, materials, or production limits.

AI for manufacturing production processes

Manufacturing processes cover many layers, so it makes sense to view AI through two angles. The first is the operational work of the shop floor, where most data is produced and most decisions happen in real time.

Predictive maintenance

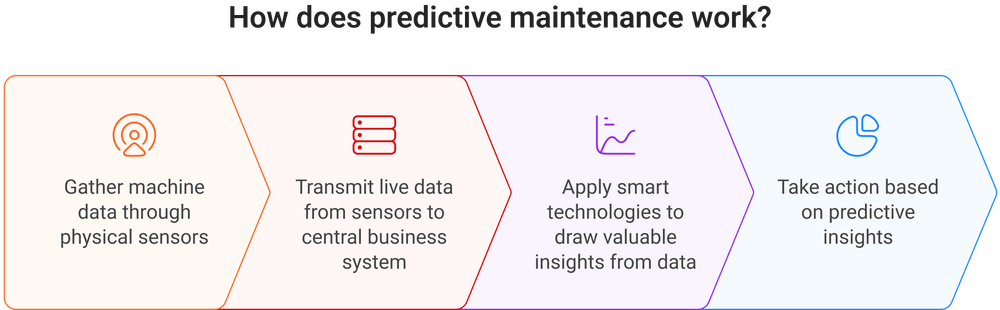

Predictive maintenance is a method that tracks the actual condition of equipment to estimate when a failure is likely to occur. It moves beyond regular checklists and uses live data to signal when attention is needed.

Many people confuse it with preventive maintenance. The difference is simple: preventive maintenance follows a fixed schedule, while predictive maintenance adapts to what the machine is actually doing.

The process relies on several technologies working together. Sensors installed on machines collect information on vibration, temperature, pressure, and other indicators. This data is sent to a management system, either locally or in the cloud.

Machine learning models then examine the incoming stream, compare it with historical patterns, and identify early signs of wear or malfunction. When the system detects an unusual pattern, it sends an alert so that technicians can intervene before the issue becomes serious.

What does this approach mean in measurable terms? According to a Deloitte study, companies applying predictive maintenance tools report labor productivity improvements of 5-20%. The same research shows downtime reductions of up to 15%, which helps keep production lines closer to their planned output.

Independent assessments reinforce these trends. Siemens analyzed predictive maintenance use across their customer base and reported notable gains:

- Forecasting accuracy improved by up to 85%;

- Unplanned machine downtime fallen by as much as 50%;

- Maintenance staff productivity risen by up to 55%;

- Maintenance costs decreased by up to 40%.

How global companies adopt predictive maintenance:

Major manufacturers treat predictive maintenance as a strategic capability rather than a side project.

Rolls-Royce reports that its digital monitoring systems help prevent roughly 400 unplanned maintenance events each year, which cuts repair costs and avoids lengthy service interruptions.

PepsiCo announced in May 2025 that it is extending predictive maintenance practices across both manufacturing and logistics to stabilize operations across its global facility network.

Automotive companies are moving in the same direction. Volkswagen points to predictive maintenance as part of its broader plan to integrate AI-driven services into vehicles and supporting systems, especially for electric models where optimized charging cycles and early diagnostics influence performance and lifecycle costs.

The heavy equipment sector is also active. Caterpillar introduced an AI-based recommendation engine that guides dealers and customers on maintenance actions.

ML-powered defect inspection

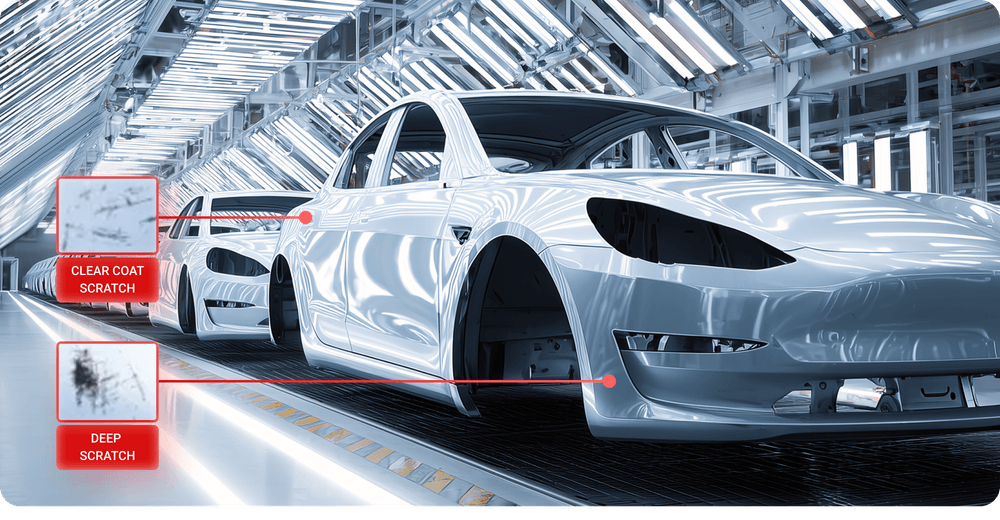

Quality control relies on identifying faults at the earliest possible stage. AI strengthens this process through computer vision and machine learning models that review images or sensor data directly on the production line.

These systems highlight shape deviations, surface defects, assembly inconsistencies, or measurement errors with a level of speed and repeatability that human inspectors cannot maintain across long shifts.

Manufacturers use these tools in different ways. Electronics plants verify component placement and soldering quality. Food and beverage facilities check packaging integrity. Automotive lines track alignment, weld quality, and surface finish. In all cases, AI reduces manual verification, speeds up inspection cycles, and supports more consistent grading.

Key outcomes typically include faster detection, fewer false negatives, lower scrap rates, and more predictable product quality.

AI-driven quality control in practice:

Unilever’s Tinsukia facility shows how computer vision can support high-volume environments. The factory reports an 85% reduction in product changeover times after introducing image-based systems that map product characteristics and detect anomalies as they appear. This shortened the transition between production batches and reduced the risk of defective items entering the next run.

Ford applied data-driven monitoring at its plant in Spain, where delays often occurred when mechanical parts wore out unexpectedly. Engineers built a system that tracks machine behavior and sends alerts to staff through a mobile app when components begin to slow down.

Since its deployment in 2019, this approach has helped the plant avoid breakdowns and generated savings of more than €1 million, while stabilizing its production schedule.

Rolls-Royce faced a different challenge on turbine blade lines, where millions of tiny cooling holes required manual inspection each month. The process was slow and often created bottlenecks. By introducing AI-based defect detection and vibration analysis, inspectors now focus only on areas flagged as questionable rather than checking every hole.

This shift increased machine utilization by about 30%, reduced scrap linked to human error, and accelerated fault resolution from days to near real time.

Generative design

Generative design uses algorithms to explore countless design options within set boundaries such as materials, size limits, or manufacturing methods. In product development, this approach helps teams move from guesswork to evidence-based decisions, testing many viable alternatives long before anything is built.

AI strengthens this process by running simulations, comparing outcomes, and narrowing the field to the most promising solutions in a fraction of the usual time.

Real-world results of AI-driven generative design:

AstraZeneca applies AI models to improve how active pharmaceutical ingredients are designed and produced. Predictive tools help refine chemical properties and simulate manufacturing performance before physical trials begin.

As a result, development lead times dropped by about 50%, and the use of active ingredients in early experiments fell by roughly 75%.

Kraft Heinz uses generative AI to speed up product creation and update existing recipes. AI reviews huge combinations of ingredients, packaging choices, and consumer preferences, helping teams pinpoint versions with the best taste and appeal.

This has shortened innovation cycles and improved the match between new products and customer expectations.

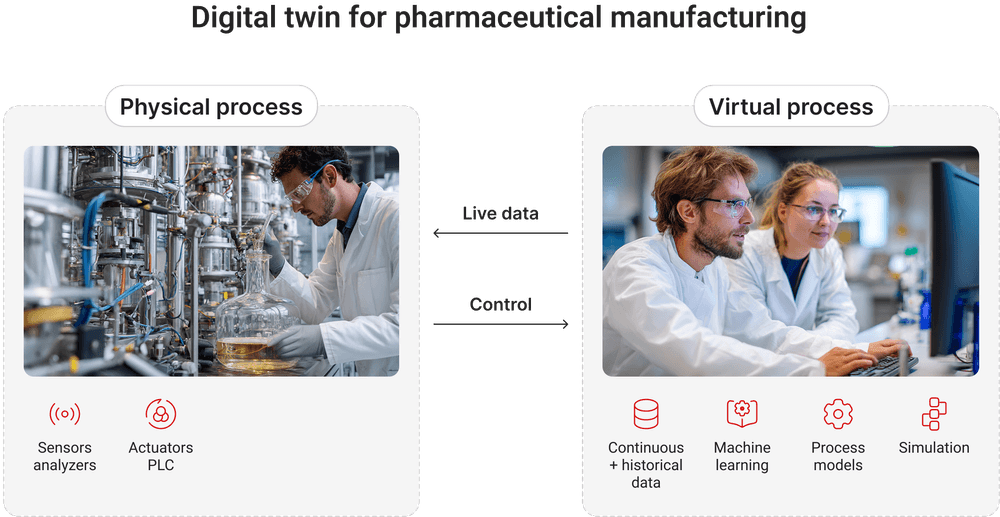

Digital twin technology

A digital twin is a virtual model of a physical asset, production line, or even an entire factory. It updates in real time using information from IoT sensors, PLCs, and AI algorithms. This constant data flow allows the virtual model to match real-world conditions with high accuracy.

Manufacturers use these twins to monitor performance, test scenarios, and adjust operations without touching the physical environment. Digital twins are especially useful in product development and factory planning. They help check layout choices, estimate resource needs, and evaluate how people and equipment move through a space.

Real results show why the technology is gaining attention. According to the McKinsey survey, about 70% of senior tech leaders are investing in digital twins. Across industries, 86% say the technology is relevant to their operations. Around 44% have already implemented a twin, while 15% are preparing to launch one.

Digital twins in real operations:

BMW built a digital replica of its production system spanning 31 plants. Changes that previously required weeks of physical testing can now be evaluated in the virtual environment, allowing for faster planning and fewer disruptions on the shop floor.

LG’s Smart Park in Changwon uses a digital twin to recreate its production line in a virtual environment. The model updates every 30 seconds and predicts potential issues up to ten minutes ahead. When the system detects a risk, it alerts workers so they can act before delays occur. This helps secure stable production and accurate part supply for mixed-model assembly.

A partnership between Atos and Siemens introduced a digital twin for vaccine manufacturing. Instead of waiting until the end of production to assess quality, teams can now evaluate and adjust processes mid-stream. The twin gathers data from every stage, improving product quality, reducing waste, and shortening time to market. It also enables safe testing of process changes before they impact real output.

Cobots

Robots on the factory floor are nothing new. They lift loads humans can’t, repeat the same motion thousands of times without fatigue, and assemble parts at speeds that would be impossible for manual labor.

What has changed is how they now fit into the workflow. Instead of being fenced off in isolated zones, many modern robots are designed to work directly with people. This shift is what turned them into collaborative robots, or cobots.

Cobots assist with tasks that are repetitive, heavy, or require high precision. AI gives them the ability to adjust their movements, recognize objects, react to changing conditions, and operate safely around human colleagues.

How real businesses use cobots:

Sanofi, a healthcare manufacturer, uses cobots at the end of its packaging lines to handle boxes weighing 3–8 kilograms. Each unit lifts between 300 and 700 kilograms per day, reducing physical strain for workers and cutting processing time by about 10%.

This improvement allowed the company to run two packaging lines with three operators instead of requiring three operators per line.

Automotive manufacturers like BMW and Ford have introduced cobots to support detailed assembly tasks. At BMW’s Plant Spartanburg, the Figure 02 humanoid robot completed trials involving precise sheet-metal fitting during chassis assembly.

Ford’s plant in Cologne uses cobots to assist engineers in delivering uniform finishing work on each Ford Fiesta, improving consistency while reducing manual load.

AI for manufacturing non-production processes

Factory floors often get the spotlight, but the quieter side of manufacturing – the offices, planning rooms, research labs, marketing teams, customer service units – is just as important for a company’s success.

Let’s look at how AI supports business & support processes.

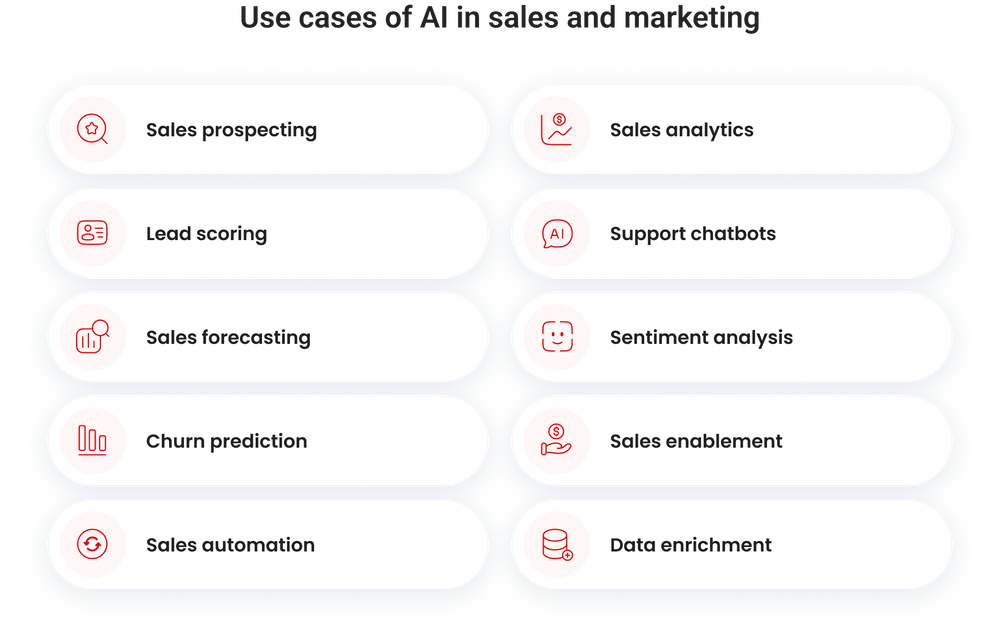

Marketing & sales

AI-driven marketing and sales rely on tools that analyze data, understand language, and generate content. These systems help teams make faster decisions, react to customer behavior, and build campaigns with more accuracy.

Generative AI adds another layer by creating text, images, and even full campaign ideas in seconds instead of days.

Modern platforms combine machine learning, NLP, and generative models to sift through large volumes of customer data and suggest the next best action. This approach helps companies stay competitive as audiences expect quick responses and more personal communication.

Where AI helps most:

- Personalization

AI reviews customer behavior, past purchases, and interests to create targeted messages, recommendations, and offers. Instead of broad campaigns, brands can speak to each segment with more accuracy and better timing. - Content development

Generative AI drafts copy, visuals, product descriptions, and campaign ideas. This shortens production cycles and gives creative teams more space to work on strategy rather than routine tasks. - Sentiment analysis

AI checks reviews, comments, and feedback to understand how people react to products or messages. This helps teams adjust quickly, solve issues earlier, and monitor reputation across channels. - A/B testing

AI sets up tests automatically, tracks results, and points to the best-performing versions. It can also predict likely outcomes using past data, helping teams refine campaigns before launch. - Sales support

AI assists with demand forecasts, lead scoring, and sales planning. Many routine tasks, such as follow-ups, notes, document updates, can already be automated, letting sales teams focus on conversations and deals.

Here you can find more application examples:

Examples of how real companies apply it today:

Heinz demonstrated how AI can transform marketing workflows. Using AI-supported tools, the company reduced content creation time from 8 weeks to 8 hours. This shift led to a 75% faster time-to-value and saved thousands of working hours across R&D, Innovation, and Marketing teams.

Danone has built a unified data platform to power its digital marketing strategy. With enriched data and new AI models, the company delivers highly personalized consumer interactions — from brand platforms to apps like the Aptamil Growth Tracker.

Their recent Actimel campaign in the UK achieved strong results:

- A 50% increase in engagement,

- A 6% boost in sales

- A 70% rise in search volume

On the production side, generative AI helped cut asset creation time by up to 50% and improved cost efficiency by 25%.

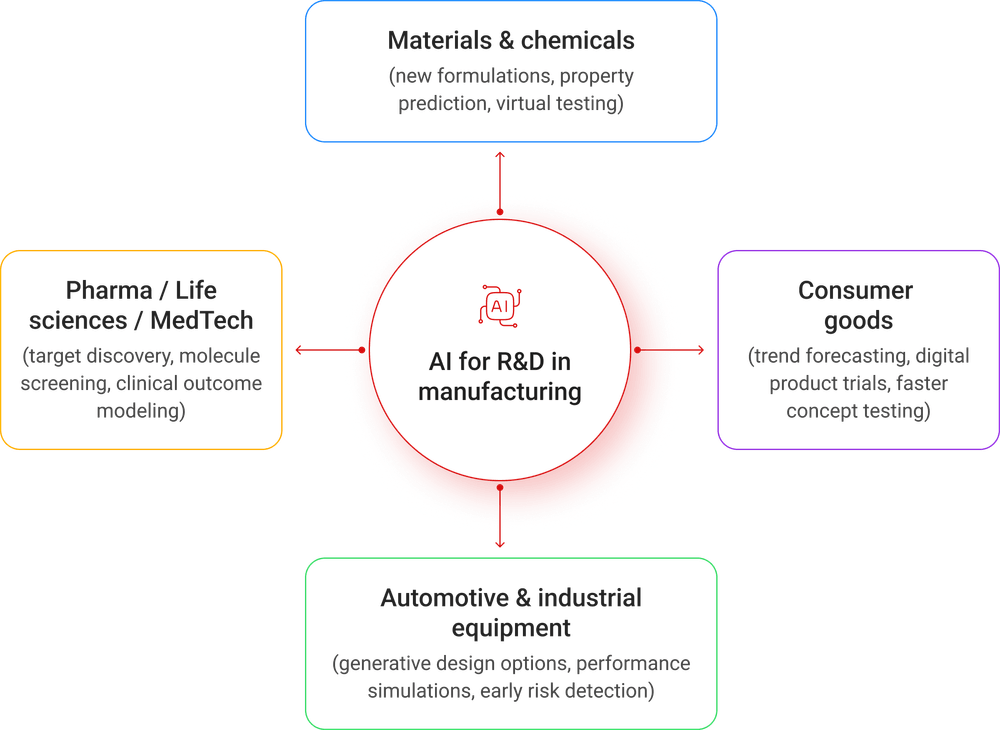

R&D

Research and development teams across manufacturing are seeing major gains from AI. Estimates show that AI tools can accelerate R&D work by 20% to 80%, depending on the sector and the complexity of the process. With the right setup, these systems shorten experiment cycles, support better testing decisions, and help teams explore more ideas with fewer resources.

AI in R&D relies on machine learning, simulation models, natural language processing, and generative design tools. Together, they help researchers review large data sets, test more options in less time, and run virtual experiments before committing to real ones. Below are several examples of how this plays out in different manufacturing segments.

- Materials and chemicals

AI predicts material behavior, suggests new formulations, and scans huge chemical datasets to pinpoint promising combinations. This helps teams screen options faster and reduce the number of physical tests needed. - Automotive and industrial equipment

Generative design tools offer design variations based on weight, cost, and performance requirements. Simulation models test how parts will behave under different conditions, helping engineers choose better designs earlier in the process. - Electronics

AI supports circuit design, detects early reliability risks, and helps refine components based on thermal performance, energy use, and durability. This speeds up prototyping and reduces late-stage redesigns. - Consumer goods

Product teams use AI to analyze consumer insights, forecast trends, and test product variations digitally. This leads to faster iterations and helps companies launch products with a clearer market fit.

The impact of AI is especially visible in pharmaceuticals, life sciences, and medical technology.

Drug development is a long and costly process: roughly 90% of drug candidates fail in preclinical or clinical trials, and it can take more than a decade to determine whether a treatment is effective. Because of this, any method that helps refine decisions earlier has enormous value.

Computational approaches support this work by improving data collection and analysis, identifying potential drug targets, predicting molecular behavior, and simulating clinical outcomes. These tools allow researchers to narrow down viable candidates sooner and reduce the time spent on unpromising directions.

Several global companies illustrate how this approach works in practice:

Pfizer used advanced computing techniques to speed up vaccine research during the COVID-19 crisis, even though the general success rate for clinical trials across the industry is only about 12%. The company also applies modeling and simulation (M&S) methods that connect laboratory, clinical, and real-world data. This approach played a role in the successful development of Neurontin (gabapentin) and continues to support ongoing drug discovery.

Roche, a global leader in oncology, reports active use of AI tools to support drug discovery and development. By applying machine learning to molecular data and research archives, the company can identify potential drug targets, refine clinical strategies, and accelerate decision-making in early research stages.

Business and administration management

AI supports business and administration teams by handling large amounts of data, spotting patterns, and offering suggestions that help people make decisions faster.

With machine learning, automation, and predictive tools, companies can plan better, simplify internal processes, and respond to changes in real time.

These systems reduce manual work, shorten processing time, and give managers a clearer view of what is happening across operations.

Below are the routine tasks where AI brings the most value:

- Document search and summarization

AI can scan emails, contracts, reports, and knowledge bases, instantly find relevant information, and summarize long texts into short, practical points. This cuts the time employees spend searching through documents and helps them get to decisions faster. - Customer service and support

AI assistants handle common questions, prepare responses for agents, and highlight relevant knowledge articles during calls or chats. They can also analyze incoming messages to route them to the right team. As a result, customer issues are solved faster, and support teams work with less repetitive load. - Training and development

AI tools can create learning plans based on employee skills, job roles, and performance data. They also generate training content, quizzes, and practice tasks. This helps HR teams maintain up-to-date programs without manually preparing every resource and gives employees more personalized learning paths. - Recruitment and HR screening

AI reviews resumes, matches candidates to job requirements, and highlights who should be contacted first. It can also analyze interview transcripts to spot common strengths or potential concerns. This reduces the time spent on initial screening and helps recruiters focus on final decisions and conversations. - Finance operations (invoice and expense processing)

AI reads invoices, extracts key fields, checks for compliance, and flags unusual entries. It also processes receipts, assigns expense categories, and prepares drafts for approval. This reduces manual data entry, shortens processing cycles, and lowers the risk of human error.

What companies see in practice:

AI-driven business operations are already showing measurable results across industries.

McKinsey reports that AI can lower HR costs by 15–20% by identifying the main reasons behind hiring needs, turnover, and performance differences, and by suggesting practical actions for improvement.

Customer-facing teams benefit as well. A Salesforce survey shows that 63% of service professionals say generative AI helps them work faster. Gartner expects that by 2025, most support organizations will use AI to improve productivity and customer satisfaction.

IBM finds that analyzing calls, emails, and tickets with AI helps companies improve service quality while reducing costs by about 23.5%.

Several companies have already demonstrated this shift in action. Panasonic uses assistive and autonomous AI in customer support. With connected data and automated service workflows, they achieved:

- 73% of conversations resolved without escalation

- 34% fewer support tickets

- 70% lower maintenance effort

Bouygues Telecom applied generative AI to analyze call center data and prepare suggestions for agents during conversations. This real-time support reduced pre- and post-call operations by 30% and is expected to save over USD 5 million.

Bottom line

AI is already deeply embedded in modern manufacturing, from the shop floor to business operations, R&D, and customer engagement. Companies are not just exploring concepts. They are running experiments, integrating systems, and refining processes in real time.

Larger manufacturers often have the scale to test multiple initiatives simultaneously, while mid-sized companies must carefully prioritize investments and validate results before scaling. In either case, meaningful AI adoption depends on understanding your data, operational flows, and realistic constraints.

At Aristek, we support manufacturers at every step of their AI journey. Before launching any solution, we conduct a thorough analysis of your data, processes, and operational context. We work with your team to develop prototypes, test them under realistic conditions, and validate that they deliver the desired results. Only when performance meets expectations do we move solutions into full production.

Book a free consultation to learn how we can help you successfully implement AI in your manufacturing processes.